RESNET Grading Of Installed Insulation

1) How to Grade Installation Quality of Wall Insulation Systems – Air permeable insulation materials work at their full rated R-values when installed free of gaps, voids, compressions and are encapsulated by air tight materials on all six sides.

2) The Residential Energy Services Network (RESNET) has established a protocol for field inspections of the installed quality of insulation materials in all wall systems. These inspections are to be completed prior to the installation of drywall by a qualified RESNET Energy Rater. These inspections and the “Grade” of installed insulation are factored into the Home Energy Rating System (HERS) modeling software and ultimately can have an impact on thermal performance; or the final assigned HERS score of the home. There is an assignment of Grades 1 through 4, with a Grade 1 installation being most desirable. Grade 4 does not have an associated diagram and if this installation is encountered in the field an Energy Rater will perform measurements in the field following the RESNET guidelines.

a. In many case the most recent building codes have adopted insulation inspection protocol and working with your energy rater and insulation contractor to achieve a Grade 1 installation will make good construction sense in working with you local building department too.

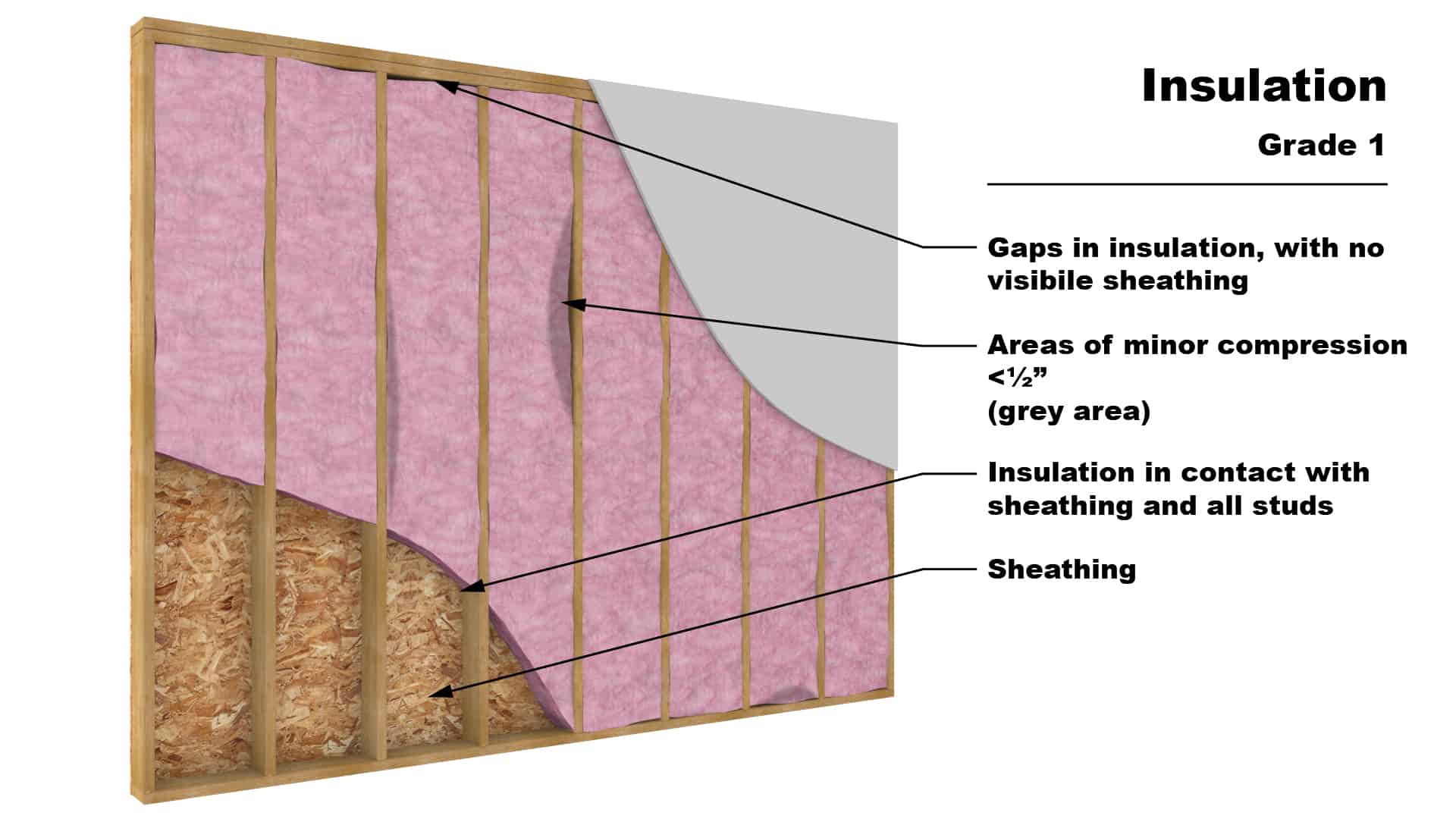

3) Grade 1 is the most top grade. Assignment of Grade 1 ensures the insulation system is installed according to the manufacturer’s installation instructions. The material completely fills the wall cavity, and in the case of fibrous, or air permeable insulation materials are encapsulated with airtight materials on all six sides. Recall, that this is a discussion about defining the air barrier on buildings and that these wall insulation materials will perform optimally with the air barrier in contact on all six sides. The material is also carefully cut around electrical junction boxes, split around wires and pipes generally not compressed greater than ½” of its thickness over less than 2% of the surface area. (See the call-outs below for the parameters)

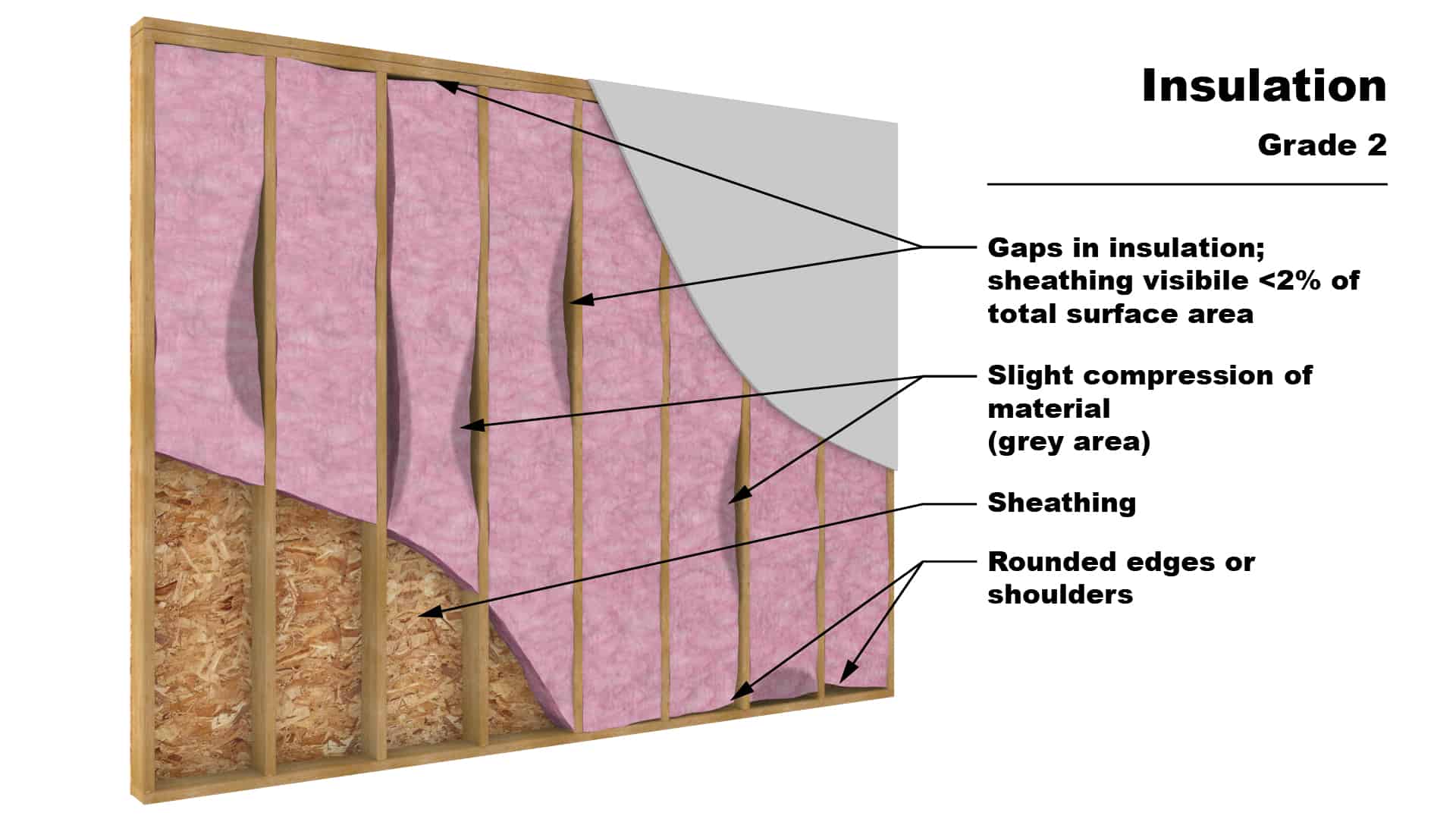

4) Grade 2 – has some allowance for imperfections in the installation, but overall there are minimal imperfections with the installed material. Minor gaps and compression may exist between 2% and less than 10% of the total surface area of typically of ½” or less. Another important note is that grade 2 requires all air permeable insulation materials are encapsulated with airtight materials on all six sides. The insulation may have slight imperfections around electrical junction boxes or very slight rolled edges on the insulation. (See the call-outs below for the parameters)

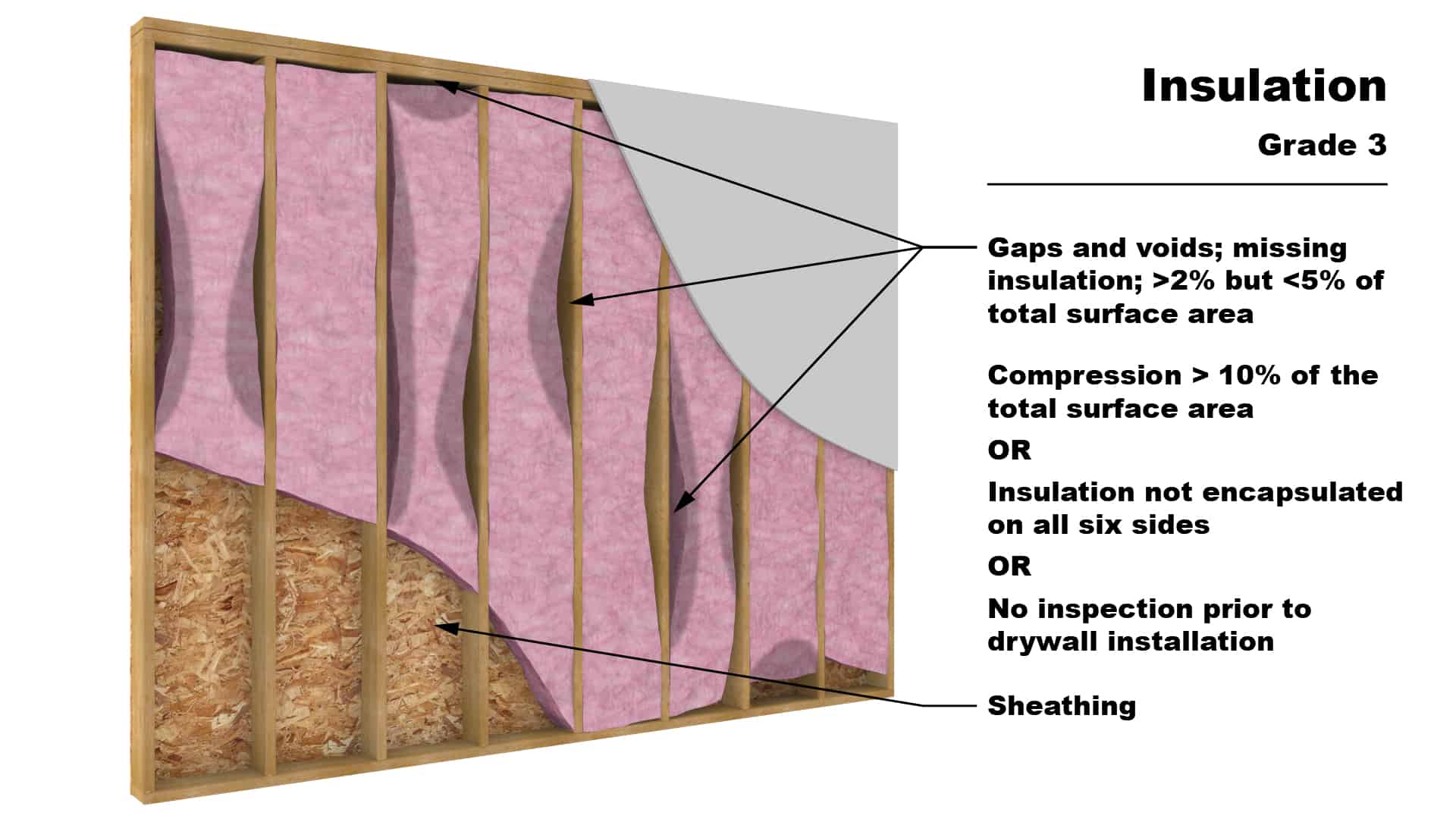

5) Grade 3 – is the least desirable outcome for an installation and should typically require an installing contractor to return and replace or repair in affected insulation systems. This installation grade indicates that more than 10% of the total surface area is compressed greater than ½” and that encapsulation has not been achieved on all six side of the air permeable insulation materials. (See the call-outs below for the parameters)